| Aircraft fuel cell development

An energy storage and power generation system being designed at the University of Louisiana at Lafayette could make flying the friendly skies less harmful to the environment. Solid oxide fuel cells are “a key component” within that system, said Dr. Xiao-Dong Zhou. Their inclusion in the next generation of electric aircraft could cut carbon emissions – and that’s caught the eye of the U.S. Department of Energy, which awarded UL Lafayette a $2.26 million grant this fall. |

|

|

Integrated Computational and Experimental Optimization of Materials and Methods for In-Space Manufacturing of Lightweight Metal Alloys (ISM-LSM) Integrated Computational and Experimental Optimization of Materials and Methods for In-Space Manufacturing of Lightweight Metal Alloys (ISM-LSM) is a collaborative research effort with strong support from NASA Marshall Space Flight Center, NASA Johnson Space Center, and in alignment with NASA Space Technology Mission Directorate roadmap objectives. |

|

Development of material properties of Inconel, titanium, and nickel alloys for process optimization of selective laser melting additive manufacturing Accurate high-temperature thermophysical property data for liquid metals and alloys are important for simulation of laser-based 3D printing processes. To understand and better control such additive manufacturing (AM) processes, knowledge of properties such as melting temperature, density, viscosity, and surface tension of liquid metals and alloys is needed. |

|

Irradiation of 3-D Printed Alloys Researchers from the C-ICME Lab are collaborating with Dr. Gabriela Petculescu from the Physics Department to study the effects of irradiation on 3-D printed alloys. |

|

Validation of Methods for Mechanical And Microstructural Property Measurement of Sub- standard Sized SLM Test Specimens According to ASTM E8, the minimum overall length of a testing sample must be 200mm (ASTM E8). The cost of SLM produced Ti64 is approximately $350/kg [1]. To cut down characterization cost, an efficient method has been developed using sub standard sample size and DIC. |

|

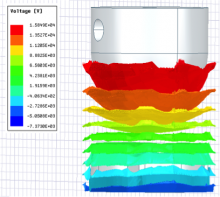

Control and Simulation of Container-less Processing of Materials by Electrostatic Levitation

The C-ICME Lab is developing a vacuum Electrostatic Levitation (ESL) system for the experimental determination of difficult to measure material properties, such as high temperature and liquid phase thermophysical properties of metal alloys. |