Researchers at the University of Louisiana at Lafayette will develop and analyze new 3-D printing materials and processes as part of a five-university project funded by a $20 million National Science Foundation grant.

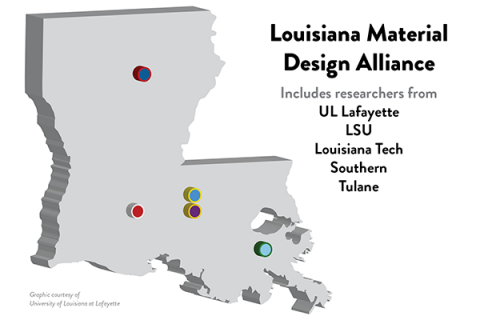

The grant established the Louisiana Material Design Alliance, a consortium comprised of UL Lafayette, LSU, and Louisiana Tech, Southern and Tulane universities. The universities will conduct research that will be shared with federal agencies and industry to address a growing reliance on 3-D printing in manufacturing. UL Lafayette’s portion of the grant is $2.7 million.

“LAMDA provides a framework for research that will include opportunities for undergraduate and graduate students,” said Dr. Miao Jin, an associate professor in UL Lafayette’s School of Computing and Informatics. Jin is leading the University’s research for the project.

“LAMDA was also created to help universities enhance curriculums and hire faculty members to educate and train students who will help fill workforce needs. It’s a comprehensive, balanced approach designed to benefit the entire state,” she added.

3-D printing, which is also known as additive manufacturing, involves creating an object from a three-dimensional digital model by “laying down” many thin layers of a material, such as metal or plastic.

The process was developed in the 1980s, and became common in industrial manufacturing the following decade. It is becoming popular in many industries now, said Dr. Jonathan Raush, an assistant professor in the Department of Mechanical Engineering.

3-D printing is used to make everything from prosthetics and jewelry, to automobile parts and computer components. It is increasingly being implemented for biomedical, energy and aerospace applications.

“Accompanying the growth of 3-D printing is a need to develop materials with a broader range of compositions and properties that make them more durable, or lighter, or otherwise tailored to specific products and applications,” Raush explained.

UL Lafayette researchers will do that by integrating elements of computer science and engineering.

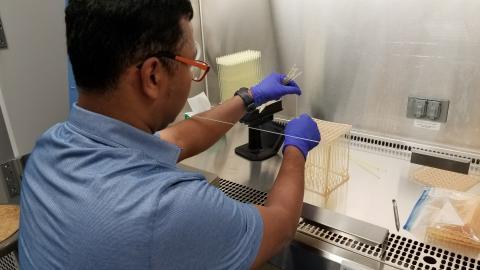

Researchers will design and analyze complex alloys and polymers. Complex alloys are created by combining two or more metallic elements. All plastics are comprised of polymers, which are long chains of bonded molecules. Not all polymers, however, are plastics.

Researchers will also test materials to see how they react to factors such as heat and pressure to gauge “fatigue” limits, or the highest level of stress a material can withstand.

The process of discovering optimal processes and new materials for specific functions will be guided by machine learning, a form of artificial intelligence, Jin explained.

Machine learning models are capable of “learning” from data and making predictions – about which 3-D printing processes or new materials are best suited for a particular application, for example.

Researchers in the School of Computing and Informatics will develop machine learning models based on information gleaned from research into 3-D printing processes and materials.

“Components can be manufactured with more complicated shapes at much lower weights with 3-D printing than with traditional manufacturing methods. The problem is a lack of existing 3-D printing materials that provide a desired fatigue life. Data analysis and machine learning will guide us to new materials or processes that are optimal for specific applications,” Jin said.