Research Significance

According to ASTM E8, the minimum overall length of a testing sample must be 200mm (ASTM E8). The cost of SLM produced Ti64 is approximately $350/kg [1]. To cut down characterization cost, an efficient method has been developed using sub standard sample size and DIC. Small testing specimens require less time to test and manufacture. There has been very few studies involving sub-standard sized SLM manufactured materials.

Testing Procedure

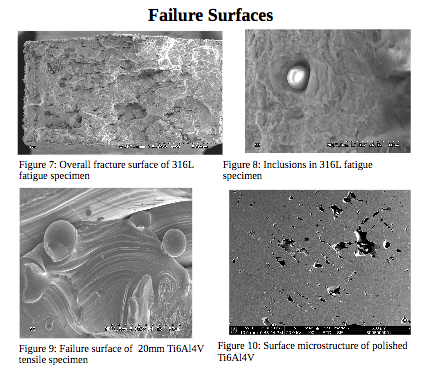

Two sets of flat dog bone (Figure 1) shaped specimens with gage lengths of 10mm and 20mm were cut from SLM printed plates of both SS316L and Ti6Al4V. The building direction of all the specimens were vertical to maintain consistency. The samples were tested using predesigned holder (Figure 2) which was put inside the MTS grip to avoid slipping. All tensile tests were conducted at a constant stain rate of 0.01mm/min. The displacements and strains were measures with DIC. Similar samples were used for low cycle fatigue tests with 20Hz cycle and R= -1. Finally the tensile and fatigue properties were compared with standard sized SLM printed samples as well as wrought samples. Microscopic images of the fracture surfaces were taken with SEM to understand the failure.